Boost Your Business Up

Ranking High Level

FOR FUNCTIONAL & PRODUCTION PARTS

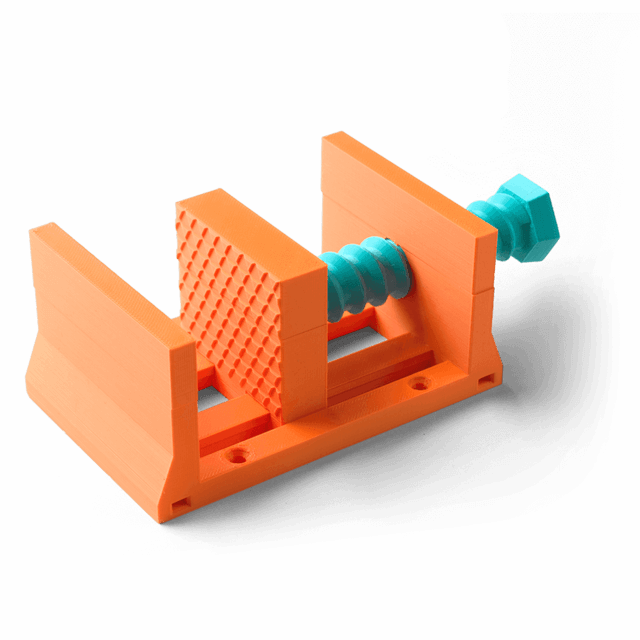

FOR RAPID PROTOTYPING (FDM 3D PRINTING)

FDM (Fused Deposition Modeling) 3D printing is a popular additive manufacturing process that melts plastic filament and extrudes it layer by layer to build objects. It’s cost-effective, versatile, and commonly used for prototyping, production, and custom parts.

SLA 3D PRINTING

SLA (Stereolithography) 3D printing is an additive manufacturing process that uses ultraviolet (UV) light to cure liquid resin layer by layer, creating highly detailed and accurate objects. Known for its precision, SLA is ideal for producing intricate prototypes, jewelry, dental models, and other high-resolution applications with smooth finishes.

FOR AESTHETICS + RAPID PROTOTYPING

FOR FUNCTIONAL & PRODUCTION PARTS

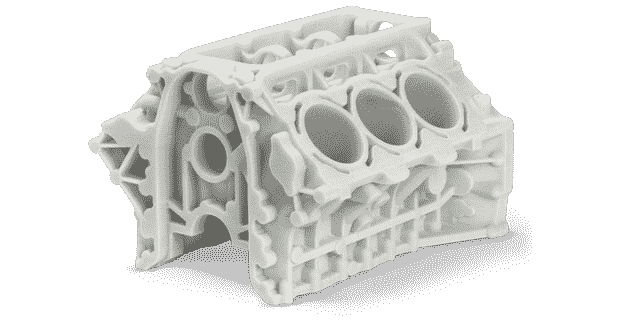

SLS 3D PRINTING

SLS (Selective Laser Sintering) 3D printing uses a high-powered laser to fuse powdered materials, such as plastic, metal, or ceramic, layer by layer. This process creates durable, functional parts with complex geometries, making it ideal for producing prototypes, end-use components, and custom parts in industries like aerospace and automotive.

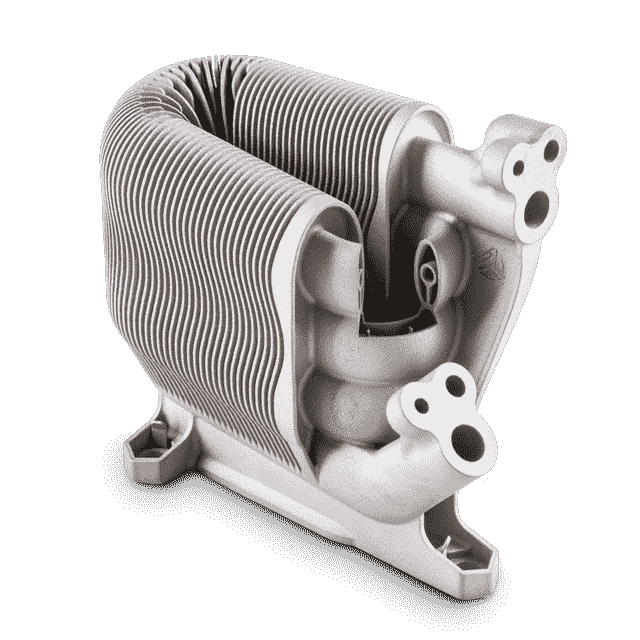

METAL 3D PRINTING

Metal 3D printing, also known as additive manufacturing, involves using lasers or electron beams to fuse metal powder layer by layer. This process allows for the creation of complex, high-strength parts with intricate geometries. It's widely used in industries like aerospace, automotive, and healthcare for custom components and rapid prototyping.

FOR INDUSTRIAL APPLICATIONS

FOR COMPLEX SHAPES

POLYJET 3D PRINTING

PolyJet 3D printing is an additive manufacturing process that uses inkjet-like technology to jet liquid photopolymer onto a build platform, curing it with UV light. This method enables the creation of highly detailed, multi-material, and multi-color parts with smooth finishes, making it ideal for prototypes, models, and complex designs.

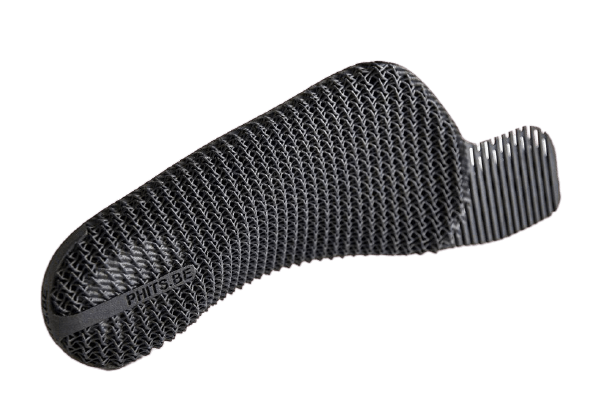

MJF 3D PRINTING

MJF (Multi Jet Fusion) 3D printing uses a high-speed, inkjet-based process to selectively fuse powdered materials, such as nylon, with binding agents and heat. This technique creates strong, functional parts with fine details and excellent mechanical properties. MJF is commonly used for prototypes, end-use parts, and high-volume production.

PREMIUM LOW VOLUME PRODUCTION