Boost Your Business Up

Ranking High Level

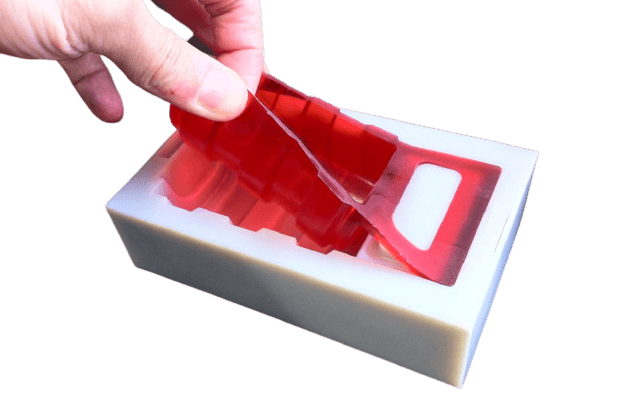

VACUUM CASTING

Vacuum Casting is a versatile manufacturing process used for producing high-quality plastic and rubber prototypes, as well as small batches of end-use parts. It begins with creating a master model, usually through 3D printing or CNC machining, followed by forming a silicone mold around it. Liquid resin is then poured into the mold under vacuum to eliminate air bubbles, ensuring precision, intricate detailing, and consistency. This method is widely used for rapid prototyping, functional testing, and short-run production.

Learn More

Competitive Pricing

High-quality parts at low cost

6000+ Happy Clients

Including ISRO, DRDO, & TATA

One Stop Platform

Track your CNC Machining

Priority Delivery

CNC Parts delivered in 4 days